Reeflections:

A Three Foot Square Challenge By: John Laurenson

It is an honor to be featured in the Reef Hobbyist Online Reeflections Column, especially considering I’m following reef keepers like JB NY, steveweast, and others. I often visit their Web sites and envy their tanks. I often sit in awe when I read and see the effort and thought they have put into their systems. My little reef tank covers less than a 3-foot square piece of floor in my condo and doesn’t seem comparatively worthy.

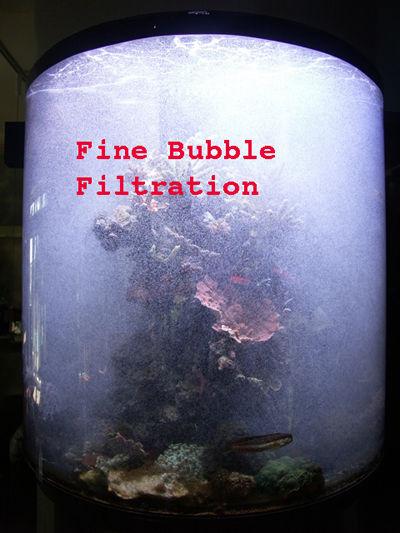

The tank is a 45 g ½ barrel shaped tank as shown below. The stand and hood extends from the floor to the ceiling, curved to match the tank, and has been made to look like a wall extension. The stand and hood are covered with aluminum laminate. All support equipment is compactly installed either under or above the tank.

Being an engineer and a “Rube Goldberg” inventor, I love tinkering with new ideas and tweaking old ones. I continue to modify my reef tank support system in an effort to make it easier for me to maintain a clean stable environment for reef life with minimal daily input. I frequently need to leave my system unattended for a week at a time.

For additional details about my system not shown here can be viewed on my Web Site.

Transitions in thinking…

I set up my system about 2 1/2 years ago. This was my first real attempt at salt water but I had a lot of preconceived filtration ideas carried over from freshwater aquariums. I decided the best approach for processing waste biologically was to do it inside the tank substrate.

I designed a DSB plenum system that was more responsive by allowing regular wasting by flushing to the drain. I called it CPW (controlled plenum wasting) to describe it. The concept was to stimulate bacteria growth within the DSB so that waste could be more efficiently processed and keep the DSB from going sour. Many reef keeper have had great success using DSB’s, I did not. After about a year it was becoming difficult to keep SPS when using this process because of phosphate and nitrogen waste being released back into the water column and nuisance macro algae growth was difficult to control. Later, when I removed the DSB, it showed heavy calcium clumping and several large black anoxic pockets. Flux from the substrate may have caused my SPS coral to RTN.

After a number of months fighting excess nutrients, I started to believe that exporting waste (detritus) before it started to biologically break down made more sense. Also detritus exporting is more easily accomplished without substrate in the tank. After a lot of thought, I spent two days changing the system and applied some different waste export methods. I also pick up a tinge of humility in the process. Following are several methods describing what I have found that seems to work well on my system for the last 18 months in keeping excess nutrients under control with minimal effort. I am sure many reef keepers will find my support system and filtration export methods interesting and maybe even a little controversial.

My present approach to exporting waste…

1. Heavy Short Pulse Circulation – To reduce energy consumption from a large pump running all the time, I use a high flow pulse recirculation system. Every 6 hours for 15 minutes a high flow rate pump is turned on giving over 50 times turn over per hour. Virtually all detritus on the tank bottom is put into suspension by the strong flow rate so that is can flow into the filter. It has eliminated my need to manually remove waste off the bottom.

2. Fine Bubble Flotation Filtration – During heavy pulse recirculation an air pump is turned on diffusing air near the pumps inlet for 2 – (1 minute) periods. The air injection floods the tank with fine bubbles for a few minutes. The bubbles attach to floating waste particles and assist in floating out the waste and exporting it to the over flow weir. The fine bubbles also causes the SPS coral to release a lot of slime as the bubbles attach to it and floating it off.

3. NPR – (Nitrogen / Phosphate Ranching to stimulate phosphate and nitrogen laden bacteria growth for exporting) I regularly dose small quantities of vodka, ½ ml per 25-gallon tank capacity, which supplies a clean carbon source that promotes bacteria growth. As the bacterium biomass grows, by using excess nitrogen and phosphate nutrients, the floss and skimmer remove it.

4. Filter Floss Exporting – The vodka is dosed into filter bags which is filled with filter floss. A highly concentrated bacteria slime bloom grows within the floss after a few hours as it is fed by the high waste laden water flowing through it. The bacteria slime starts to die and slough off in about 24 hours, so I remove and replace the bacteria laden floss 8 hours after dosing vodka. The floss removed is loaded with bacteria slime. Floss is never kept in the system more than two days so that it does not become a nitrate factory.

5. Vodka dosing is done daily, until P is non detectable in the water column and/or nuisance algae is eliminated, and then less often to maintain low P. This helps me to maintain low phosphates throughout the system and it also keeps the tank nuisance algae free.

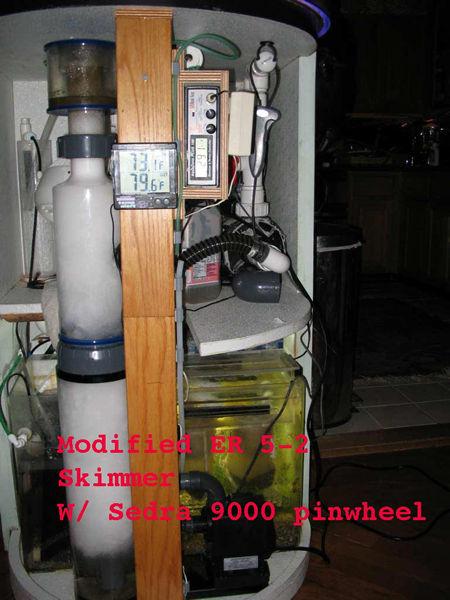

6. An over sized skimmer is required to keep up with bacteria removal when dosing. I modified my ER to improve performance. It works well and removes nearly a gallon per week of black goop that drains into a gallon milk jug.

7. And just as important regular semi weekly 25% water changes.

My basic maintenance has been reduced a 10 minute job every other day; feed the fish, clean the tank front, dose vodka, and remove dirty floss. Once a week I empty the gallon jug and clean the tank with a magnetic pad. Everything else is automated with my computer and X-10 controllers. Hopefully I will never need to rebuild the system again. I have had to leave the tank unfed and unattended for over 5 days with no adverse affects.

In reef keeping, every system is unique with it’s own demands. The bioload is different for every system. There is no single best way to keep a system. I don’t advocate anyone use my methods. They are detailed to stimulate thought. The often bantering conversations on the Internet’s reef keeping forums with other members has given me an advanced degree in reef keeping in a few short years. I am continuously amazed at the depth knowledge of many members. Give me another 10 years and I might get my PHD in reef keeping.

Support Equipment

Stand Construction – Plywood construction using 2 sheets 3/4” plywood glued to make a 1-1/2″ structure. Plywood inside is covered with plastic laminate.

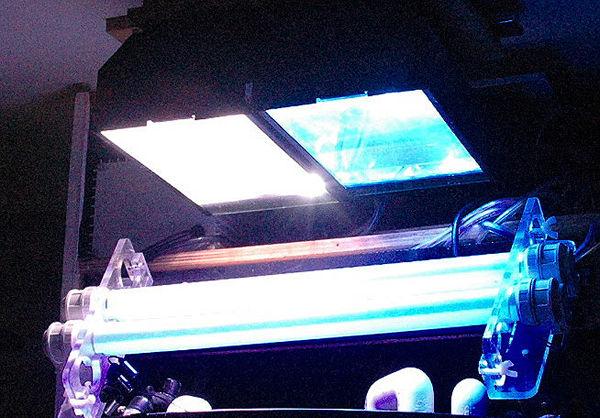

Lighting – DIY Hood and reflector:

(2) DE 250 watt Metal Halides(10k: 9am – 4pm and 15k: 8am – 8pm)

(2) 75 Watt 24” actinic VHO (7am – 12pm)

(2) LED moonbeams – on 24 hours