Beginners Journey: Overflows and Sumps

By: Scott Zachow

Most aquarists use sumps on their marine tanks for various reasons. The two main reasons are to add water volume to the system and to provide a place to keep vital equipment out of sight. For the seasoned aquarist, a sump is useful for most setups. For those new to the hobby, “sump” may be an unknown term and once it’s researched, installing a sump can be a scary proposition due to the dynamics of the setup. Although a sump is defined as “a low-lying place that receives drainage,” to the aquarist it is typically “an external water container placed under the aquarium.” The seasoned aquarist most likely will not acquire any new information from this article. It is my intention for this article to answer any questions new hobbyists have regarding sumps, their setup and their operation.

I first will expound on the reasons for using a sump on your marine aquarium. Beyond the two main reasons mentioned above, several secondary reasons are also important as someone advances through the hobby. These external containers can hold equipment such as heater(s) and protein skimmer(s), and they can also help to eliminate water movement devices because they inherently use a pump in the setup to return water from the sump to the main tank. For the addition of advanced equipment such as chillers and calcium reactors, a sump provides space for the placement of the pumps needed to power them, and is an easy placement for their effluent. New hobbyists often have been encouraged to maintain as large a system as they can fit and afford when first starting out. The reason for the “larger is better” recommendation is that changes in water conditions generally happen more slowly with larger volumes of water. Smaller systems might benefit the most from sumps, because the percentage of added volume from the container is relatively higher in smaller systems than in larger systems. A 20-gallon aquarium with a sump that holds 10 gallons of water has added 50% of the total water volume to the system. The same sized sump under a 100-gallon aquarium, although still beneficial, has added only 10% of the water volume to the system. For systems of 100 gallons or greater, the added water volume probably isn’t the greatest gain from setting up a sump, but remains one of the two main reasons to do so. In all situations, the sump is often a more suitable place for vital equipment than the display tank. Hobbyists striving for a naturally appearing marine display have huge hurdles to cross when heaters, powerheads and various tubes and plumbing obstruct the view. All of this equipment can become so unsightly that the aquarist is faced with a no-win situation, and the display’s appearance suffers. A sump is an effective solution to this problem and in some cases helps the equipment operate more effectively.

Figure 1:

Figure 1: A simple diagram showing a display tank with a sump sitting under it. This diagram shows that the sump is not completely filled with water, an important feature that allows for drainage from the display in the event of a power outage.

With all of its benefits, why wouldn’t everyone use a sump in their setup? The answer is mostly that sump dynamics seem complex and the danger of a flood seems high. Because we have a container that holds water under the tank, and therefore have to move water from the display to the sump and then back again, people fear floods, overflowing tanks and using a professional plumber to install it. In reality it doesn’t require much work, isn’t out of the reach of even the semi-handy aquarist, and with a little planning can be set up to be “fail-proof.” The cost isn’t prohibitive, either; setting up a simple sump can cost as little as $100.

The Components

There are three simple components in a sump system; the container, the return pump and the internal/external overflow from the main tank. Each of these three components can vary in complexity and cost, but their technical operation is the same. We have to get water from the tank into the container and back again. Most importantly, all of this has to happen continuously and simultaneously. If any of them work without the other, the famous words of Apollo 13 Commander, Jim Lovell, may come into play: “Houston, we’ve had a problem.” The good thing here is with proper planning, we can easily prevent two of the three components from causing any problems; the third being the container, because if it breaks or leaks then perhaps there will indeed be a problem.

A common misconception that many people new to the overflow/sump concept have is that two pumps are needed, one to pump water to the sump and another to pump water back to the tank. Although logic says this is what is needed, in reality it could never happen successfully. For this concept to work, both pumps would have to move exactly the same amount of water constantly. Even if someone could get this to happen at any given point in time, it would never happen constantly because pumps get dirty at different rates and build up calcareous scale deposits at different rates, and a number of other changes occur that affect their outputs differently at different times. Luckily for us there is gravity, which eliminates the need to pump water to the sump.

Figure 2:

Figure 2: Water can never be pumped to and from the sump at the exact same rates. This would result in either the display tank overfilling and the sump pump running dry, or the pump moving water to the sump operating at a higher rate and slowly draining the display and overfilling the sump.

Figure 2: Water can never be pumped to and from the sump at the exact same rates. This would result in either the display tank overfilling and the sump pump running dry, or the pump moving water to the sump operating at a higher rate and slowly draining the display and overfilling the sump.

There are two common ways to get water from the display tank. Both allow for a constant water level in the display tank as controlled by the return pump. The first and best method is with a display tank that is drilled, allowing water to simply drain into the sump. Being built-in, this is the best method as it does not require an additional hanging device, and although the other method I will discuss is usually safe, this one is definitely the safest.

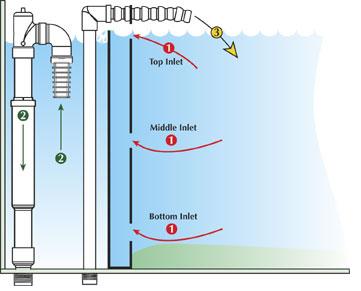

Figure 3

1. Water flows in from the bottom, middle, and top inlets and spills over the overflow’s inner wall into the reservoir.

1. Water flows in from the bottom, middle, and top inlets and spills over the overflow’s inner wall into the reservoir.

2. Water passes through the drain pipe and out of the tank to the sump.

3. Water is pumped back into the tank

Images courtesy of All Glass Aquariums, www.all-glass.com.

With this type of drain system, the only considerations are the amount of water the drain can accept and the return pump’s rate. Let’s look at the sequence in reverse order. Water is pumped from the sump into the display tank. As the water in the display tank rises over the top of the overflow wall the chamber behind the wall begins to fill with water. As this chamber fills up to the opening in the drainpipe, water is fed by gravity back into the sump. As long as the amount of water pumped into the display does not exceed the capacity of the drain pipe, the water level in the sump will stop dropping, the water level in the display will stop rising and the exact amount of water that is being pushed to the display will also drain back to the sump through the drainpipe. If the amount of water returned to the tank from the sump exceeds the drainpipe’s capacity, the tank will overflow, the sump will empty, and the return pump will run dry.

Likewise, the same considerations must be made with the other type of device that allows tank water to drain into the sump, an external overflow device. This is a hang-on-the-tank unit that is used on standard display aquariums that are not and cannot be drilled, due to their tempered glass construction. The external overflow box runs on the same principle as the internal overflow except that it uses siphon tubes to move the water from the display to the external overflow box, which contains the drainpipe to drain the water to the sump. Some additional considerations must be made with these types of overflows. First and foremost, you must ensure that the overflow’s manufacturer lists it as a continuous siphon overflow. This should ensure that when the return pump is not operating, the tubes that siphon water from the display into the external overflow will remain full of water and will therefore begin to siphon water again as soon as the return pump starts back up. If these tubes do not maintain their siphon, however, when the return pump resumes operation the water level in the sump will continue to fall and the level in the display will continue to increase, and most likely will overflow. Some precautions can be used such as a small powerhead with its output aimed into the siphon tube, or an air pump connected to the tube to resume the siphon. Even with these precautions, the siphon tubes may not hold their siphon or restart after the pump begins operating, which will result in a mess. The other consideration is that these units require more maintenance than a drilled tank’s internal overflow to ensure flawless operation. The tubes that are used to siphon the water often fill with algae and other growths, which reduce their potential drainage capacity. Therefore it is necessary to remove and clean these tubes occasionally. Finally due to the size of the external overflow box, it is difficult to build drainpipes inside them, such as the Durso and Stockman style standpipes. These are drainpipe modifications that can be used in place of a straight drainpipe, for noise reduction. Straight drainpipes (or water just flowing through the bulkhead) are very noisy and often make a “flushing sound.” The Durso and Stockman standpipes virtually eliminate any noise from the draining water.

Figure 4:

Figure 4: A typical external overflow box is shown above. The image shows the clear internal box with its surface skimming groves; the two U-tubes that siphon water from both the display and the external overflow box, which contains the bulkheads; and the pipes, which drain water to the sump.

The second component in sump design is the return pump. Many, many types of pumps are available that will work for any application, and many pumps will not work as they may be too strong or not strong enough. When purchasing a pump to use on your sump setup, you must get one that will push water the through the return plumbing the distance required to get it to the display. Therefore you must find a pump that can push water to at least the height from the sump to the top of the display, and still move a satisfactory amount of water through that height. Typical powerheads will not work here. You will have to get a pump that can withstand significant wear and perform constantly. With this consideration, understand that the gallons-per-hour rating applied to the pump cannot be used to determine how much water it will actually move under these circumstances. As an example, a pump rated at 900 gallons per hour will probably produce a total flow through of only 700 gallons per hour after the water travels through and up the return plumbing.

When using an external overflow box, you should target a minimum flow rate as well. If an external overflow box is rated at 600 gallons per hour, a pump that moves only 200 gallons per hour may not be enough to keep the water flowing quickly enough (and constantly enough) through the siphon tubes. Therefore for both types of drains, the drilled aquarium and the external overflow, you should try to reach, but not exceed, the drain’s maximum capacity with your return pump.

Regarding the return pump, a few other factors can help to guide your decision. Obviously cost is an important one, and the price of usable pumps for sump applications can range from 50 to several hundred dollars. It is possible to use internal, submersible pumps or external pumps. Each has pros and cons, including ease of setup and maintenance, space required and noise. Another consideration is power consumption, at least for those interested in conserving energy.

The final component in the sump and overflow application is the sump itself. As stated at the beginning of this article, a sump is nothing more than an external container or vat that accepts drain water and, as such, for an aquarium application it can be just that simple. A standard sized aquarium that fits in the available space under the display tank can be used with no modifications. This is, of course, the sump’s simplest form. Many people include a couple of baffles in the sump, just before the return pump, to help diffuse air bubbles. These prevent, or at least reduce, the amount of tiny bubbles that find their way into the return pump and the display, which can be unsightly and even irritating to the tank inhabitants, as well as causing cavitations in the pump. Baffles are simple dividers in the sump, placed just before the return pump in a configuration that makes water flow under and over them in a series. Sumps can, however, take on a whole new dimension of filtration. Some sump systems on the market have built-in protein skimmers; provide a section for a refuge tank; have bulkheads drilled through their side for chillers, calcium reactors, kalk reactors, plankton reactors and other devices; have mechanical filtration in the form of sponges and filter socks; and have many other “bells and whistles.” The beauty is that nothing in the dynamic of the overflow/sump design changes; water still flows from the tank to the sump and is then pumped back to the tank. Whether the sump that is used is a simple aquarium or a complex acrylic filtration device, one major factor must be considered: the sump must be large enough, or its operating water level must be low enough, to accommodate all residual overflow from the tank without flooding the sump. Failure to allow for this will result in saltwater on the floor and some frustrating work with a mop.

Flow Discussions

A slightly advanced topic with regard to sumps and overflows is the capacity of water that can be pushed through the system. This concerns not only how much water can be passed through a pipe, but also how much water should flow through the sump. The volume of flow through the sump really depends on the aquarist’s desires; however, some things need to be considered. For example, if a skimmer is placed into the sump, enough water must circulate through the sump to pass plenty of unskimmed water to the skimmer. Likewise, the same requirements exist for a chiller, or any other device that might be fed by sump water. If a protein skimmer is circulating 1800 gallons per hour, yet only 200 gallons per hour flow through the sump, there will not be enough new water passing through the sump for the skimmer to skim. This is not to say that the skimmer will run dry, but that it will continually reskim water that was just skimmed. Therefore, you need to make sure that you are passing enough water through the sump to meet the needs of the equipment and to keep it operating at its most efficient. As a general rule, the return pump should move five times the volume of the tank per hour through your sump. This means if you have a 75-gallon tank, the return pump should move at least 375 gallons per hour through the sump.

The more water that is moved through the system, the more difficult it is to have a “bubble free return” and the more turbulence there will be in the tanks and associated vessels. Bubbles are the biggest problem and may be resolved with the use of baffles as previously mentioned; however, it is not possible run 1000 gallons per hour through a 10-gallon sump and not have bubbles. In such a situation, all of them can never be removed. The associated turbulence is also too great, and will cause a lot of splashing and unwelcome noise. Sumps with incorporated refuge tanks add another factor that must be considered, as it is typically more desirable to have a bit less flow through a refuge environment than you would have without one.

Knowing the capacity of the drainpipes and ensuring that the return pump does not exceed this capacity is of critical importance. When designing the aquarium system, the first determination is what the sump’s function will be. The second is to determine how much flow needs to pass through it. Once these decisions have been made you must make sure that the drains can pass that much water, per hour, to the sump via the internal or external overflow. Manufacturers of external overflows provide a “gallons per hour” rating on their devices, which is typically between 600 and 900 gallons per hour. If you want more water to pass through the system, a second external overflow device may be required. For internal systems, these ratings aren’t readily available but can be determined. For most standard reef ready aquariums, the tank is drilled with a drain hole for a 1” bulkhead, which can drain about 850 gallons of water per hour. Flow rates of different sized pipes can be calculated by using the formula for the area of a circle: A= π*r2. Using this formula, it can be determined that the opening of a two-inch pipe is about 3.14 square inches (3.14 x 1.0 (1×1) = 3.14). So, in theory, a single 2” pipe has exactly the same area as four 1″ pipes (3.14 x 0.25 (0.5 x 0.5) = 0.78), and therefore could easily handle 3400 gallons of water per hour. In practice, the capacity of four 1” pipes is significantly lower than the capacity of one 2” pipe because the friction, i.e., water resistance, in the pipes with the smaller diameters is much higher. However, back to the basics; just make sure that your pump does not exceed the pipes’ capacity.

Conclusion

I hope that this article has demonstrated some of the components and dynamics of setting up a sump system. For new hobbyists, it is probably the first system upgrade that will occur. Its benefits are substantial and the acquisition and setup of the components are simple. Don’t let the concept scare you as you progress on your Beginner’s Journey.